Formwork systems

for segment girders of Bridge & Tunnel constructions

Technology, designation, fabrication & more…

General instruction of our design & fabrication capacities

Regarding civil infrastructure, HUAN YU’s strong suit lies on fabricating steel segment shape systems for Bridge/Tunnel reinforced and prestressed concrete casting and Steel bridges. In addition of our world-class fabrication facilities, there are a 60 persons’ design-team to respond to the market demands. China has built over 37,900 km of high-speed rail by the end of 2020, accounting for more than 2/3 of the world’s total. Of this 2/3, Huan Yu has taken its fair share, that is we have completed more than 400 projects by now worldwide.

For your project, we have the funds, the production facilities, the intellectual capacities, the RIGHT professionals, last but not the least, the EXPERIENCES to enable us to catering your project with quality and efficiency. Creating value for our customers is our guiding motto.

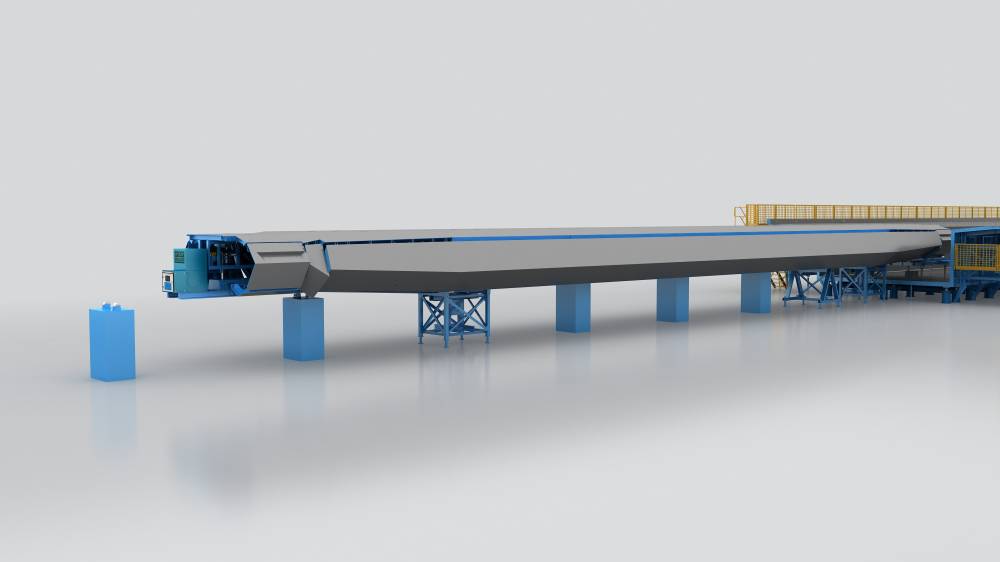

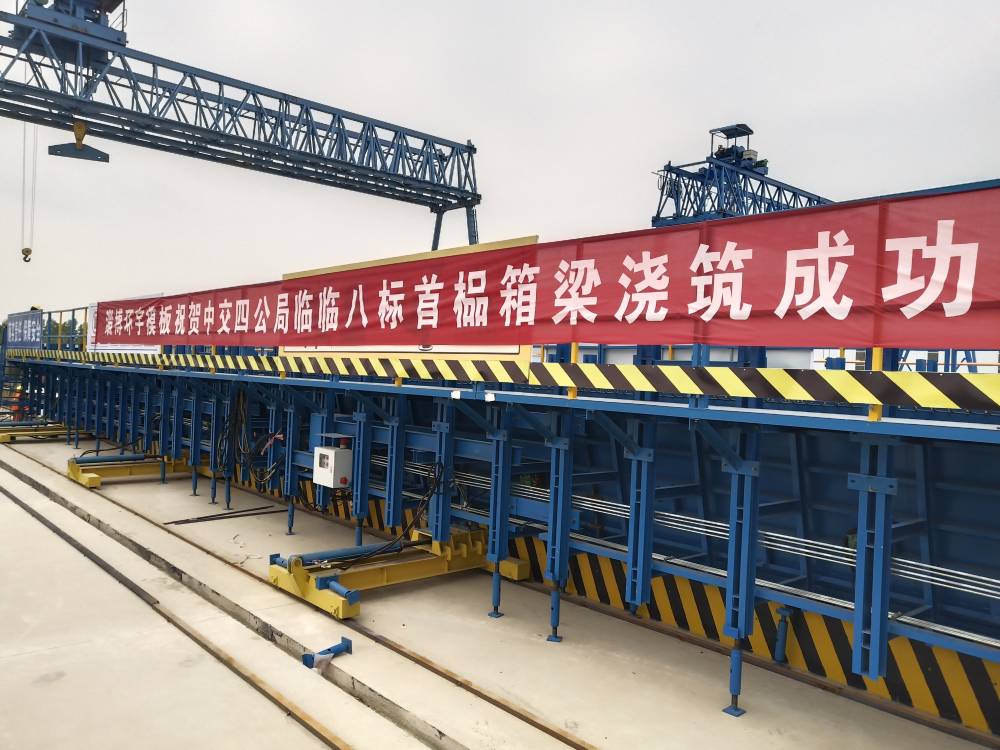

Formwork for prefabricated box girders

(hydraulic or manual operating system)

Prefabricated Box Girders

General descriptions:

Customized design & fabrication:

1.jpg)

Formworks for prefabricated box girders, T-Beams

General descriptions:

Segment shapes for U-shaped girders

General descriptions:

Segment shapes for segmental beams

long-line or short-line method

Tunnel lining pours

Steel structures

Trusted Partners

Our company has been growing up with the development of communication infrastructures in China. We have participated most of the major bridges & tunnels constructions either in highways, metros, or high speed railways.