Safety & Efficiency

are the bigger savings

In accordance with the design, dimensions and details required by the segmental bridge projects, one needs a more accurate casting forms in order to establish the desired lines and grades.

The very apparent advantages of the precast segmental bridge construction are: fast segment fabrication speed, smaller casting site, easy erection and geometry accuracy. I can also reduce the construction equipment, simplify the cosntruction process, suitable for continuous or simply supported bridge structures.

Product characteristics

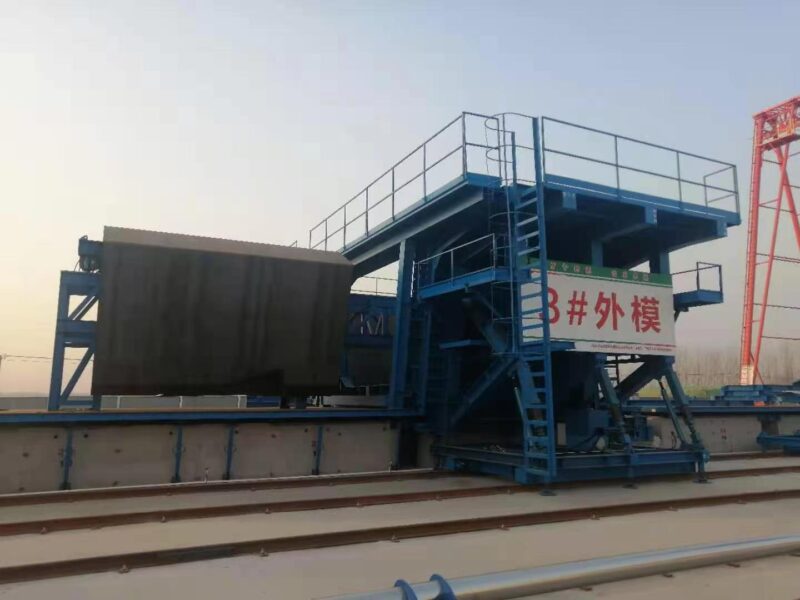

Concrete casting form for segmental bridges.

This precast segment casting form system consists of fixed vertical bulkhead of the cross section shape at one(long-line method)/both ends(short-line method), side forms, core forms with movable supporting system, and soffit with trolley.

Complete production lines.

Designing and fabricating in one place!

Product information for exportation:

85 professionals from graduates to senior engineers.

Our design team is big enough to have the age diversity advantage. While experiences safeguard our professional sense, knowledge calculates the precision of the structures.